“Innovative always… since 1985”.

Product Gallery

Video Gallery

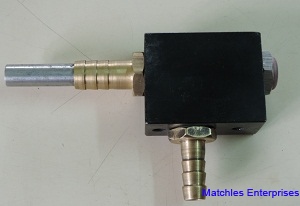

Suction Gun Assembly

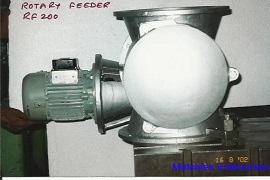

Rotary Atomizer Assembly

Suction Gun Dismantling

Rotary Atomizer Dismantling

Matchless Enterprises

S. No. 39/1A, 39/2, Wadgaon (Bk),

Manik Baug, Sinhagad Road,

Pune – 411051

India

Address:

S. No. 39/1A, 39/2, Wadgaon (Bk),

Manik Baug, Sinhagad Road,

Pune Maharashtra 411051

India

Telephone: 0091-020-24355940

Email: dsd@matchlessenterprises.com